To enable the Government’s achievement of its legal target to bring all greenhouse gas emissions to net zero by 2050, it has issued a draft amendment to Approved Document L for both new and existing dwellings. This document sets out the Government’s plans regarding U-values for windows and external doors that are intended to take effect in Spring 2022.

New performance targets were established following a Government consultation with a focus on environmental and energy efficiency issues. Many of the issues and concerns raised regarding the energy efficiency of buildings went beyond the scope of the consultation proposals and the existing Building Regulations. They addressed: embodied carbon; Modern Methods of Construction; suggestions for how we can further address the performance gap of new buildings; and actions that will be required to ensure consumers are familiar with, and have the confidence to use the products and spaces they occupy, in smarter, greener ways.

The changes show an interim uplift for 2021/22 that the Government considers will deliver high-quality homes that are in line with our broader housing commitments and encourage homes that are future-proofed for the long-term. These homes will be expected to produce 31% less CO2 emissions compared to current standards.

This is the first step in the Government’s move towards their Future Homes Standard and further changes are expected for implementation in 2025 that could see U-values drop to levels now applied in Passivhaus standards.

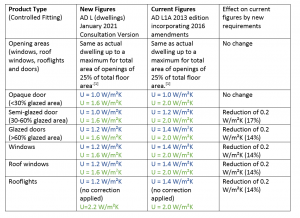

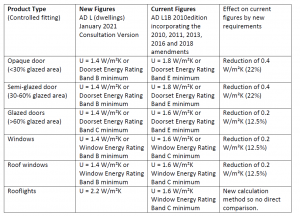

Changes to U-values as stated in new Approved Document L for dwellings (new and existing)

New Dwellings – Notional Building targets and back-stop U-values

The notional building or target figures are shown in blue

The back-stop figures (i.e. no worse than) are shown in green

Work on existing dwellings – replacement windows and doors, new openings and extensions

These are minimum performance figures (i.e. similar to back-stop, or no worse than, figures for new build)

Guidance on improving U-values for Windows

Rules for improving whole window U-values

(3.1) Reduce the frame factor i.e. the frame as a percentage of the total window area

(3.2) As the frame area reduces so the glass area will increase

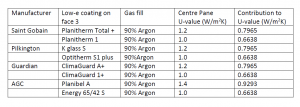

(5.1) select an improved low emissivity coating

(5.2) select an improved gas mix for the cavity (e.g. Krypton is better than Argon which is better than air)

(5.2.1) ensure the cavity width is the optimum size for the gas mix. (e.g. 16-20mm is best for air and argon but 8mm is better for Krypton)

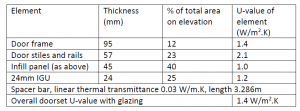

Example of changes to a typical BR 443 style, or model flush casement timber window

1280 wide x 1480 high with a central mullion, one opening casement and no projections to the head or sill (i.e. frame components are flush without head drip or sill nosing)

Total area of window Aw = 1.8204 m2

Area of frame components = 0.6121 m2 (34%)

Area of glass units = 1.2083 m2 (66%)

*The frame components and glass unit will contribute to the overall U-value of the window in proportion to their areas, while the warm-edge spacer bar will contribute in proportion to its total length

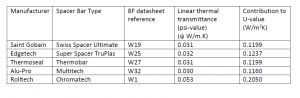

This information is taken from the BF (Bundesverband Flachglas) datasheets https://www.bundesverband-flachglas.de/en/downloads/bf-datenblaetter-fenster

Area of glass = 1.2083 m2

The glass producers have online tools that will give the performance characteristics of various types of glass unit where the number of panes, the type of coatings and gasses can be changed to see their effect on the overall figures.

Pilkington Spectrum – https://spectrum.pilkington.com/

Saint Gobain, Calumen – https://calumenlive.com/

Guardian, Glass Analytics – https://glassanalytics.guardian.com/

AGC Glass, YourGlass – https://www.agc-yourglass.com/gb/en

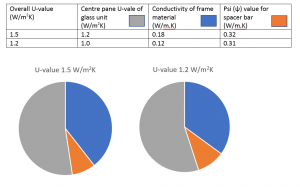

These pie-charts show the contribution of the window elements to the overall U-value using different figures

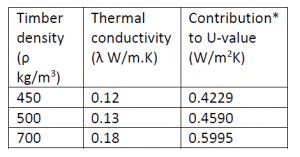

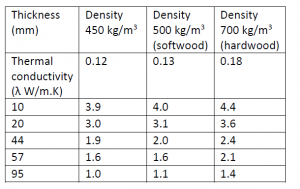

Typical U-values of various thicknesses of timber

Thermal conductivity of typical insulating materials

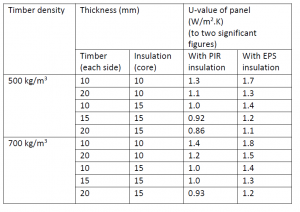

Typical U-values of insulated timber panels. (Two faces of timber either side of an insulating core)

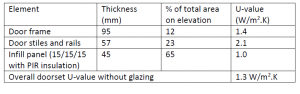

U-values of BR443 doorset 1000w x 2100h (total area 2.1 m2) with main components formed from hardwood (density 700 kg/m3, thermal conductivity 0.18 W/m.K)

Unglazed

Glazed