Shortlist: Product Design In Wood Award

Shortlist: Product Design In Wood Award

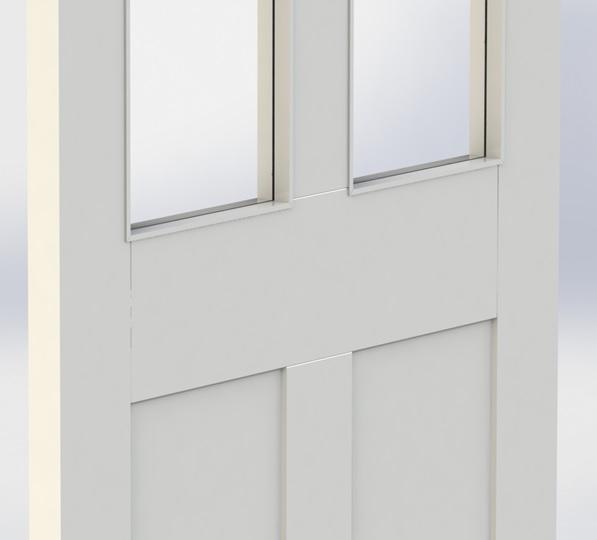

Project: To design and manufacture a Moulded FD30 Glazing Innovation

BWF Member Firm: Jeld-Wen UK

Type of work/product(s) produced: Doors, Windows and Stairs

Towards the end of 2016 JELD-WEN will be launching their latest product design innovation for the domestic market – a brand new FD30 slim profile glazing bead for moulded glazed interior doors.

Domestic glazed fire doors frequently come under scrutiny for their aesthetics, particularly when standard non-fire rated glazed doors with slimmer beading are installed in the same development.

This innovative solution is aimed at improving the industries ‘accepted’ aesthetics of large beading on glazed fire doors, and brings about a unique, contemporary system that does just that!

Innovation:

Innovation:

Through a programme of design, development, fire testing and production trials, JELD-WEN have now proven the success and compliance of this glazing system to provide up to 30 minutes fire integrity for a moulded door.

This new glazing bead will be introduced toward the end of 2016 as the standard specification across JELD-WEN’s extensive range of FD30 moulded glazed fire doors, and is certified under the BWF-Certifire scheme.

The patent pending system (GB1611416.7) will be unique in the market place, offering customers the option to upgrade their homes with a mixture of glazed FD30 fire doors and standard glazed doors (where applicable), matching the look throughout the property. This is particularly convenient when carrying out a loft conversion and the homeowner is required to upgrade doors to FD30 performance throughout escape routes.

Design & Development:

The R&D team at JELD-WEN took on the challenging brief to design and develop an innovative solution to having a glazed moulded door that could offer 30 minutes fire integrity, whilst keeping the same external aesthetics to a glazed door without fire performance. Many indicative fire tests and production trials were completed, before putting the product through an extensive testing programme to obtain evidence for BWF-Certifire certification.

The traditional larger beading visible on timber fire doors was geometrically critical to the performance of the system. The aim was to conceal these critical components within the door itself so it is no longer visible.

The traditional larger beading visible on timber fire doors was geometrically critical to the performance of the system. The aim was to conceal these critical components within the door itself so it is no longer visible.

Jeld-Wen UK developed the system taking into account the glass behaviour under fire conditions and designing the internal mechanism to support the glass. This enabled them to have flexibility with the design of the external visible beading, creating an improved aesthetic without impairing the fire performance of the glazing system.

Not only does this development improve the aesthetics of the door, but it also means that the critical components that contribute to the fire integrity of the system are protected within the door core. This also solves the problem of damaged beading through abuse/lack of maintenance that is all too often seen on fire doors, which ultimately puts the fire integrity of the door at risk.

The BWF Product Design in Wood Award rewards excellence in technical innovation, application, and achievement innovation in joinery product manufacture and design. This is a new award – splitting out 2015’s Technical Award – to recognise innovation in design and technical excellence for a specific product, rather than a project. The 2016 Award is sponsored by Teknos.